Manufacture of PTC and Nano Carbon Paste

| Section | Attached Picture | Content |

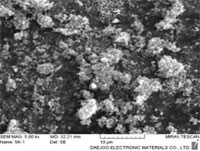

| Identification of raw material properties |  |

Arrange raw materials suitable for carbon paste.Use fillers and resins with low electrical resistance and excellent adhesion and good bending properties.. |

| Adjust recipe |  |

After grasping the physical properties of each raw material, determine the appropriate blending ratio for printing |

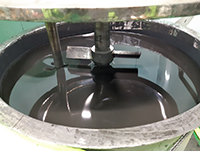

| Mixing |  |

Mix in large pot in order for mass production |

| Mixing work |  |

Use a vacuum twin mixer equipped with two large and small impellers to ensure good mixing between raw materials. |

| Dispersion work |  |

Disperse the raw materials with sufficient mixing using a 3 roll mill. |

| Inspeciotn |  |

It depends on the inspection result whether or not the conductive ink that has been pre-dispersed can be used.Slide glass, bendability, and other tests are used to inspect the product. |

| Product Release |  |

After the inspection is confirmed, the paste is subdivided into a container and shipped. |

Laboratory measuring device

Slidax

Slidax

Digital leakage current meter

Electic Power Analyzer

Heating Stirrer

Electronic wave measuring device

Tester

Laser heat Measure device

Withstand voltage tester

Oven

Micrometer

Transformer

Stirrer

Viscocity Measure Device

Applicator Bar

Thermal image camera

Precision mulit tester

Non Resistance Measure device

Twin mixer

3mill roll(12”)

3mill roll(2.5”)