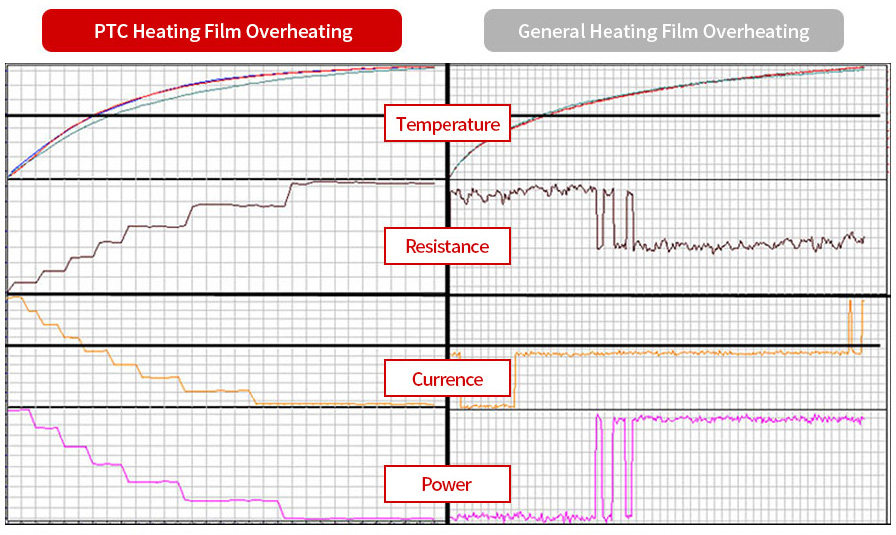

Definition of PTC heating film

PTC (Positive Temperature Coefficient) heating element is a product which controls temperature according to thermal environment. The nanoparticles of the carbon paste resin increases the resistance according to the thermal rises. If the temperature rises to a certain level resistance value is increased to control the power and current, and to prevent overheating by reducing the amount of heat generated. This product can become a third-generation heating film having a function of suppressing power consumption by an economical and safe heating. (24 hours must elapse before full restoration is possible)

PTC Heating films condition

During overheating the resistance value, current value, power value should reduce according to temperature change

If repeatedly used the initial resistance value should be maintained within heat tolerance.

Test of PTC Heating Film and General Heating Film (Test report without thermometer as to test in extreme situation)

All of the test data was made under ISK200, Sigma 6000. It is not arbitrary data by computer graphic.

RexVa Certification of Patent of PTC Heating Film

Patent Number : 10-0889195

Application Number : No. 2007-0069058

Filing date : 2007-07-10

Registration date : 2009-03-09

Title of Invention : The Carbon Paste of Self Regulate heating for Heating Film

Inventor : RexVa Kim Ho Sup

The Advantage of PTC Heating Film

| Index | 220w/m2 Heating Film | PTC Heating Film |

| Over Heating Risk | Risk | Lessen Risk |

| Consumption of Electrical Power | No Change of Power | Reduce the Consumption power during overheating |

| The efficiency of warming system | Normal | Superior efficiency & Safety |

* When the temperature of the film changes from 30 ℃ to the current amount, the temperature is controlled, and when it reaches 60 ℃, the amount of current decreases by 10 ~ 30% and lowers the probability of overheating depending on the power (W) of the heating film and local overheating area.

PTC Heating Film Test Data

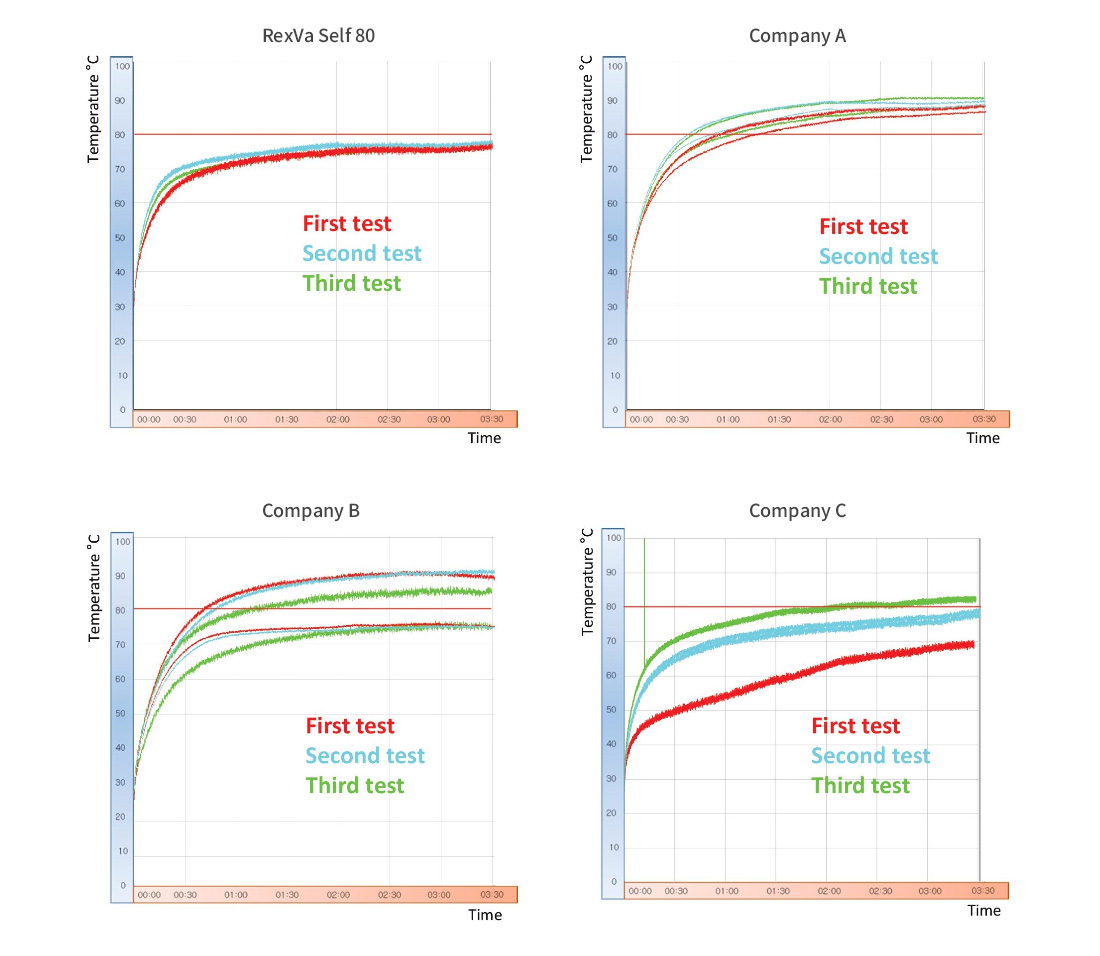

Local overheating comparative test

The purpose of the test:

Testing of RexVa PTC Self 80 heating film in overheating condition.

Comparison of RexVa PTC Self 80 film with another manufacturer's PTC film.

Testing method:

Films are connected to the network 220 volts without temperature controller.

The films are located temperature sensors at an equal distance from the edges.

Films are covered with Monolium flooring and a carpet.

Duration of testing 3 hours 30 minutes.

Test results:

The RexVa film holds a lower temperature than Company A, and don't get overheated.

The temperature difference between the sensors is noticeably higher for Company A, with less uniform heating.

Reasons for the success of the Rexva Self80 heating film

Carbon paste Unique, patented technology of production of carbon paste and quality equipment allow printing carbon layer on the film with uniform thickness, so that the temperature of our film has minimal differences across the width.

Silver Busbar. This silver Busbar reduces the energy loss along the entire length of the RexVa film. In the RexVa PTC Self 80 film, we use an exceptionally solid 18 mm thick silver Busbar.

Copper Busbar. In our film we use 15 mm wide copper Busbar, which also has a positive effect on the durability and temperature of our film.

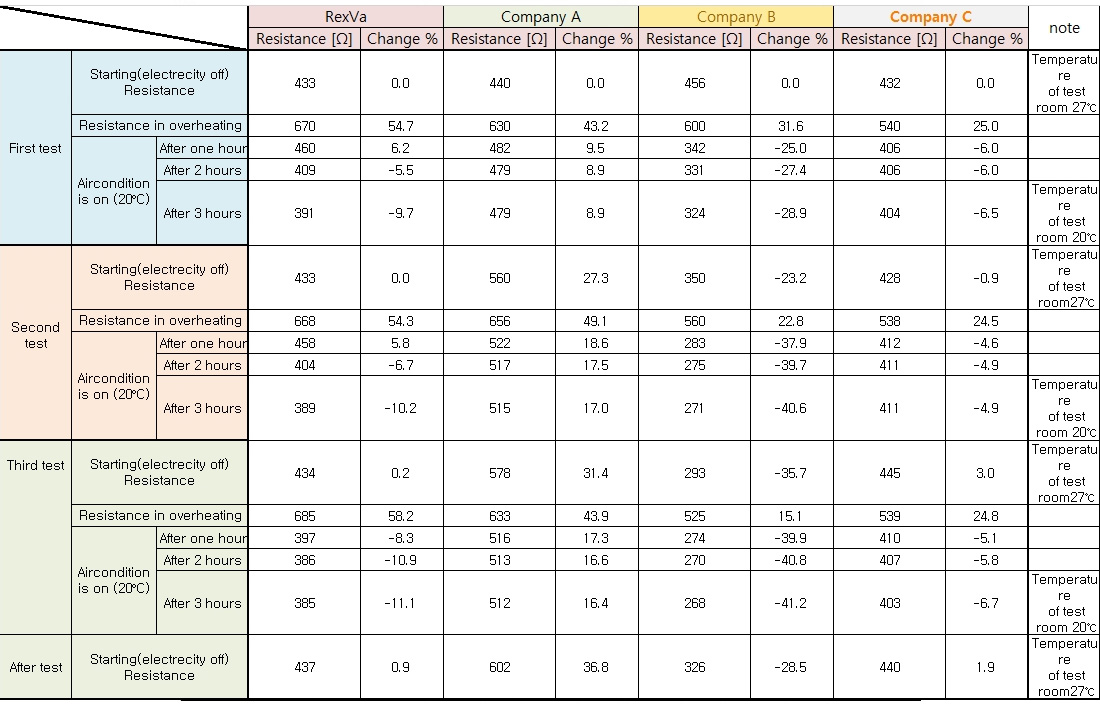

Restore rate test.

1. One of the main indicators of PTC film quality is the restoration function that returns the heating value to its original state after local overheating.

2. When the temperature rises due to local overheating on the PTC film, the resistance value increases to suppress the flow of current and to control the temperature.

3. When the power is turned off and the temperature drops, the resistance value should return to the state before the heat generation, and there should be no abnormality in heat generation.

4. After local overheating, if the resistance value is higher than the existing, the heating temperature is low due to the decrease in the wattage value.

The film should return to its initial values in 24 hours at room temperature. To speed up this process, we measure the resistance of the film immediately after the test for local overheating and place it in a conditioned room with a temperature of 20 ° C.

You can see the measurement results in the table below:

Measurement results:

By the data we can see that RexVa heating film has been stable, not allowing overheating above 80 °C and stably returning to the beginning of resistance after overheating. Films from other companies analyzed as part of the testing are having trouble keeping overheating within safe limits. Also, after the tests they greatly change the resistivity values, respectively, and as result power of the film, its economy.

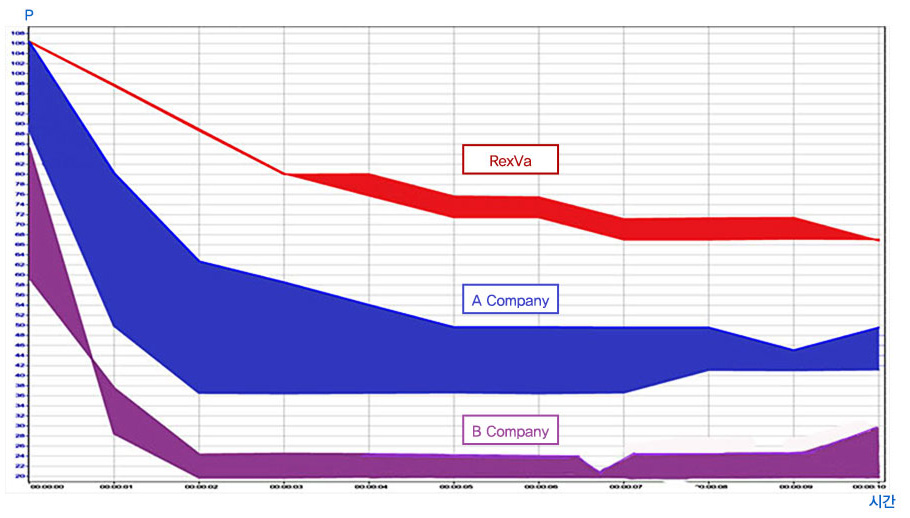

The Power change Graph of Energy Saving PTC Heating Film

First step, each company heating film is operated

Second step, each heating film is cooled fully and operated again

The Heating film must be able to make accurate power after primary and secondary heating as the initial power (Resistance should be no difference)

If heating film power is different every time when it is used, The Heating Film cannot make accurate heat and has the probability of overheating when it is used prolongedly.

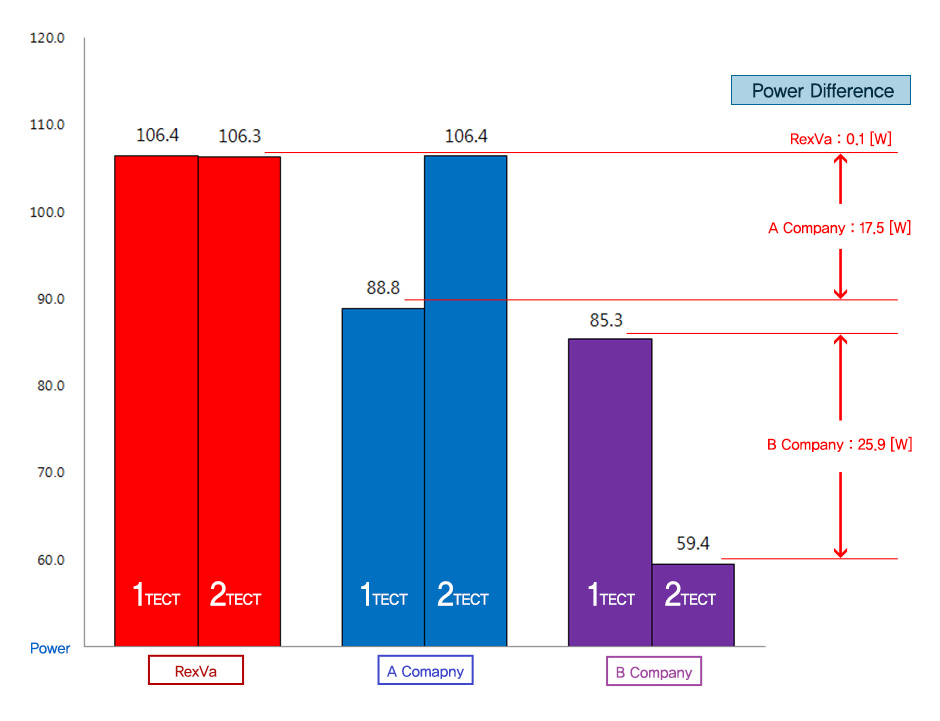

The Power(Watt) recovery graph of Energy Saving PTC heating Film

| Number of Test | RexVA | A Company | B Company |

| Primary | 106.4 | 88.8 | 85.3 |

| Secondary | 106.3 | 106.4 | 59.4 |

| Power difference value | 0.1 | -17.5 | 25.9 |