Carbon Paste

Carbon paste for the area for generating heat of XiCA Film Heater

ㆍ Carbon black is mainly from C (Carbon) like Diamond and used for automobile, ink and cosmetics. During manufacturing processes, heat treated material from 1,000 to 3,000℃ named Carbon fiber and heat treated material over 2,500℃ named Graphite fiber

ㆍ Graphite has higher Heat resisting characteristic compared to other material, lower thermal expansion coefficient, excellent thermal conductivity and electric conductivity and is widely used for the material for generating heat by electricity.

※ According to carbon and graphite mixing rate of carbon bend which is the part for generating heat of heating film, adhesive degree and resistance value can be adjusted.

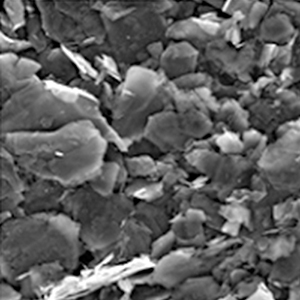

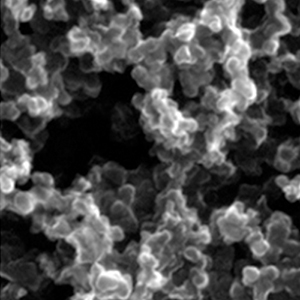

| Division | Graphite | Carbon Black |

| First particle size | 5~25㎛ | 50~100㎛ |

| shape | Flate, square shape | Spherical shape |

| Image |  |

|

Carbon Paste

| Product name | Carbon Paste |

| Composition | Carbon, Graphite |

| Drying condition | 90℃ X 2min |

| Electrical resistance | ≤ 0.1 Ωcm |

| Features | Good Adhesion on PET Film |

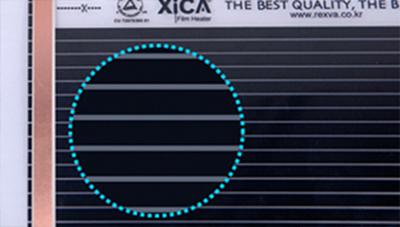

| Image |  |

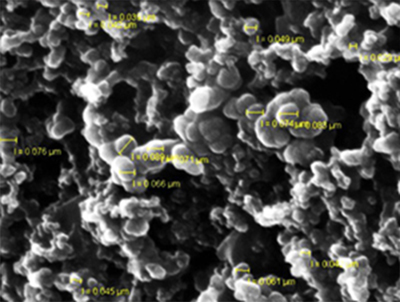

Particle size of carbon ink surface phase heating element and heating

| FE-SEM (magnification 120,000) analysis | |

| Size range | 29~90nm |

| Size shape | Spherical powder shape |

| Image |  |

Silver Paste

Silver paste for the area for conducting heat of XiCA Film Heater

When the resistance value of the silver paste of the heating element is high, there is a problem in spark generation and safety, and the lower the resistance value of the conductor, the higher the electrical conductivity and efficiency.

- Silver paste, material of electric conduction paste of XiCA heating film, has the superior printing features, the high conductivity, the excellent flexibility and the excellent viscosity with P.E.T and Laminex as the low temperature type of electric conduction paste used for heating element

Application field of product: electric conductor of heating element, Membrane Switch, EL Keypad, Touch Screen, and Keypad covered electrode for electromagnetic waves.

ㆍ Features of product: the good adhesion with PET film and the film for touch screen, the high conductivity, excellent curving and cupping strength.

| Product name | Composition | Drying condition | Electrical resistance | Features |

| Silver Paste | Ag | 130 ℃ X 3min | ≤ 0.7 X10-4 Ωcm | Good Adhesion on EL Sheet, ito Film Good Adhesion on PET Film |

Resistance value measurement chart for Silver paste by each manufacturer

| Manufacturer | Measured value | ||

| 1st | 2st | 3st | |

| RexVa | 0.3Ω/0.5㎝ | 0.3Ω/0.5㎝ | 0.3Ω/0.5㎝ |

| Local A Company | Impossible to measure | Impossible to measure | Impossible to measure |

| Local B Company | 3.1Ω/0.5㎝ | 3.1Ω/0.5㎝ | 4.4Ω/0.5㎝ |

| Local C Company | 25.3Ω/0.5㎝ | 18.7Ω/0.5㎝ | 21.1Ω/0.5㎝ |

| Local D Company | 373KΩ/0.5㎝ | 29.8KΩ/0.5㎝ | 181KΩ/0.5㎝ |

| Foreign A Company | 2.2Ω/0.5㎝ | 2.1Ω/0.5㎝ | 4.2Ω/0.5㎝ |

| Foreign B Company | 0.6Ω/0.5㎝ | 0.5Ω/0.5㎝ | 0.6Ω/0.5㎝ |

Measure method

After taking a sample of 3 parts of the entire silver surface, measure it at 0.5 cm intervals with a resistance meter.

Measured from the back of the copper foil busbar that does not overlap with carbon.

P.E.T Film

P.E.T Polyester (Polyehylene Terephthalate)

PET, the main material of upper part of XiCA heating film is the new material in the 20th century and environment friendly material with safety in the 21st century and is widely used for our life as the essential material.

Characteristic of P.E.T film

Widely used for electric insulation material for generator, transformer and etc. due to excellent electric insulation characteristic

Applied for sensitive area against heat like film, coating area due to low thermal shrinkage

Strength and modulus of elasticity are high

High durability for chemical reaction

Effects protecting ultraviolet rays

Noxious substances by cremation are very low

Laminate Film

XiCA insulated film material of heating film

Film materials for heating must use film materials for electrical and electronic use only

| Section | Main application | Detailed application | Breakdown voltage | certification for anti-flammable | Color | Price |

| Polyester film | For graphics | Plate making, Label | No data | No | Transparent | Inexpensive |

| For display | For expand plate of display | No data | No | Transparent | Inexpensive | |

| For electric /electronic | For covered wire, insulated wire, anti-flammable wire | 125 17Kv 188 19Kv | VTM-2 | Need to add insulated chip, Color like milk (translucent) | Expensive |

P.E.T physical properties chart of XiCA heating film

| Section of Physical properties | Unit | Main value | Testing method | ||

| Thickness | ㎛ | 125 | 188 | Micrometer Method | |

| Tensile strength | 60 | kgf/㎟ | 21 | 20 | ASTM D 882A |

| 80 | 23 | 22 | |||

| Elongation | 100 | % | 160 | 160 | |

| 50 | 130 | 130 | |||

| Modulus of elasticity | 80 | kgf/㎟ | 370 | 320 | |

| 100 | 380 | 360 | |||

| Thermal shrinkage | 50 | % | 1.2 | 1.2 | TSI Method (150℃/30Min) |

| 80 | 0.2 | 0.2 | |||

| Haze | % | 55 | 65 | ASTM D 1003 | |

| Dielectric breakdown voltage | kv/AC | 17 | 19 | ASTM D 1505 | |

Film material of XiCA Film Heater has superior insulation characteristic due to high turbidity.

| Application | For electric insulation, for electric part |

| Features | UL746B : RTI Electrical 105(℃) Mechanical 105(℃) |

| Certification for anti-flammable: VTM-2 |

E.V.A

EVA

E.V.A (Ehtylene-Vinylacetate) is used as the adhesive used for laminating in the heating film manufacturing process.

For the heating film, adhesion of the laminating part is very important to prevent moisture penetration in the film, heat resistance, and sparks due to the formation of an air layer. Heat deformation temperature: 80 [℃]

Manufacture

01 Design the pattern for heating Film

Design or use the product design requested by the customer ,and We manufacture products according to customer's request with power consumption data etc.

02 Raw Material Purit & Composition Design

Mixing design refers to the mixing ratio of raw materials used in the heating film, and the process of designing power consumption by varying the ratio according to the use and solvent

Setting hardening condition of Paste: Heat analysis (DSC), test for dissolving hardened material and etc.

Measure of Viscosity of Paste: Brookfield HBT-DV II, SC4-14@25°C ± 0.5,10rpm

Volume Resistence : R(Ω) x T(μm) x H (mm)/L(mm)

Hardness measurement: Pencil hardness tester

Measurement for Filler contents: Heat analysis (TGA), IGR

03 Doping Process

After conducting pretreatment, spread the paste of carbon and silver as the main material on existing design of circuit pattern.

Fidelity of film pretreatment is the process that affects the viscosity of product and can technically support the weak parts due to humidity

04 Heat treatment process

In order to maintain uniform resistance of the heating part, a high-temperature heat treatment process for complete drying is essential

Process that directly affects product safety due to chemical properties of fully dried diluent

Little change in low value due to the double heat treatment process

05 Insulation Laminating Coating

Conduct the insulation coating using EVA

Process that has a decisive effect on product insulation and moisture prevention performance

06 Quality inspection

BT (Bare Test: electric capacity test) After manufacturing the film, the process which tests the basic electric performances by multi-tester such as electric defects of products, In other words, Open & Short (Short of circuit), insulation interval deviation and etc.

Test fixture (JIG) should be prepared and tester types are dedicated type and universal type

Final Inspection After the electrical performance test is completed, other defects on the surface of the film, that is, coating of copper foil, surface condition of processed copper foil, floor smoothness of laminex, shape and material, materials used, composition of Patten, etc. Focusing on conformity to the customer's purchase specifications, film heater manufacturing technology, management technology, or errors include temperature measurement, other measuring instruments (Vernier Calipers, Dial Gauge, Pin Gauge, Angle Block Gauge), and cosmetic defects. Check by magnifying glass inspection and visual inspection.